A cleanroom is a controlled environment that significantly reduces pollutants such as dust, airborne bacteria, and aerosol particles by filtering them out in order to provide the cleanest area possible. Cleanrooms are used to manufacture all different types of products, but at Dynamic 3PL we use our clean room to minimize food contamination in the gummies industry. Not only does the tightly controlled environment keep food products safe and reduce product recalls but it also extends the foods shelf life.

Cleanroom technology is applied in the food and packaging operations with processes that cannot be performed in a closed machine. Microbes attach to airborne particles and when food products are exposed to that air, there is opportunity for airborne contamination. In order to prevent this, cleanrooms work by first circulating outside air with a filter system, which clean and decontaminate the air according to specifications. The new clean, filtered air is then forced into the cleanroom while contaminated air is pushed outside the room by registers.

Contamination comes from many different sources such as the facility itself, air conditioning debris and equipment, all of the supplies and mainly, people. Not only does the air need to be consistently filtered but there are other protocols and employee training that need to be followed.

Two important ways to maintain the highest level of cleanliness:

One critical process is Gowning. Anyone who will be entering the cleanroom must be in the correct protective clothing. Since humans are full of uncontrollable particles, it is vital that this step is taken correctly. Depending on the cleanroom class, this could mean a gown and gloves or a full head to toe suit with a mask and gloves. Generally, there will be a “cleaner” area where employees change into their gowns/suits. Employees must be aware not to wear perfume or jewelry and have a change of shoes with them and understand how all items must be put on.

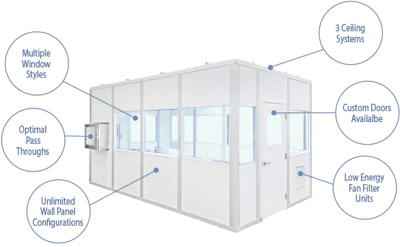

Another vital factor is the construction and materials of the cleanroom. The panels should be easy to clean and provide a sanitary surface in the processing environment. The areas where the panels meet the floor, ceiling or each other need to be precise and the proper installation to prevent water leaking in needs to be accounted for. Ceiling lights should be sealed off, and doors/windows should be custom made to fit the cleanrooms class specifications.

Although proper training and material set up are the top factors when using a cleanroom, there is a lot more that goes into selecting the class of the cleanroom, engineering it, and understanding how many air changes there needs to be per hour. It can be a lengthy and complex task to take on but is worth it. After being utilized in other industries, cleanrooms have found themselves very useful in the food packaging industry by providing safe environments for sensitive foods and is becoming beneficial to many food suppliers.